|

After much delay due to Covid and other university disruptions, Chris received First Class Honours in 2021 for his research and dissertation about wicking beds.

He delivered a webinar about the project for the Small Farms Network Capital Region soon after. Watch the webinar recording. I've now finished writing my dissertation on the results of my wicking bed research for a BSc(Hons) with Charles Sturt University. I looked at how well various reservoir media wicked water and the effects they had on soil moisture and plant growth. I will write a summary of these results, but in the meantime if you're interested in the full version, you can download my dissertation here.

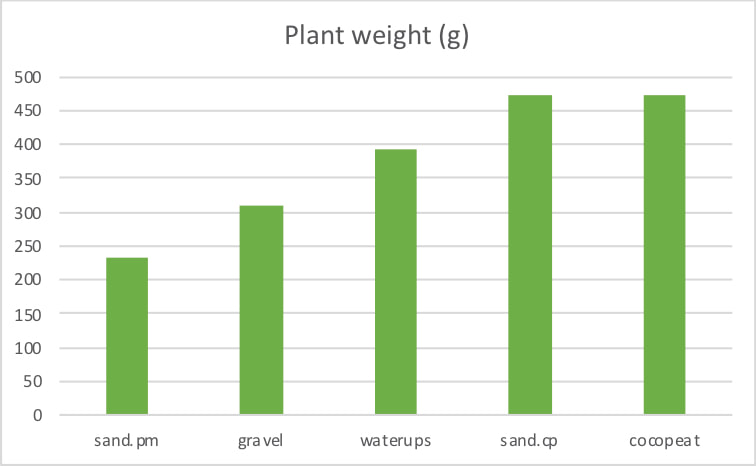

The preliminary results from my first wicking bed experiment are in. I have more analysis to do to understand the significance of these results and I have another experiment under way that will provide more data. So I don't regard this as the final answer as to what's the best way to construct a wicking bed but it does provide some insights. This experiment tested four reservoir media: washed sand, 10mm gravel, WaterUps, and a mix of cocopeat, compost and sand. Two growing media were used

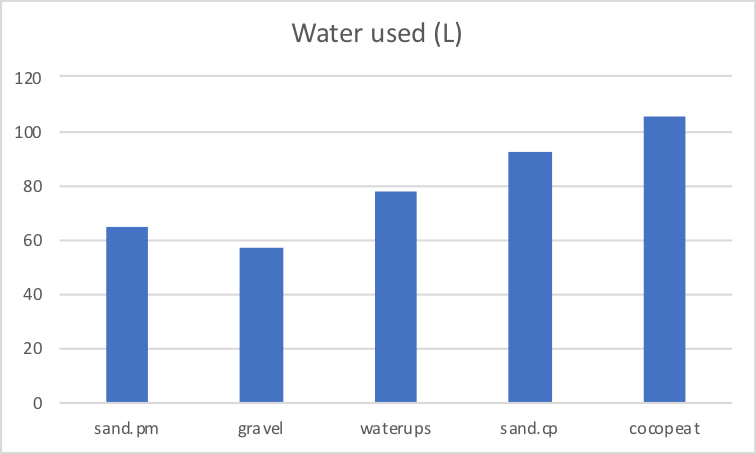

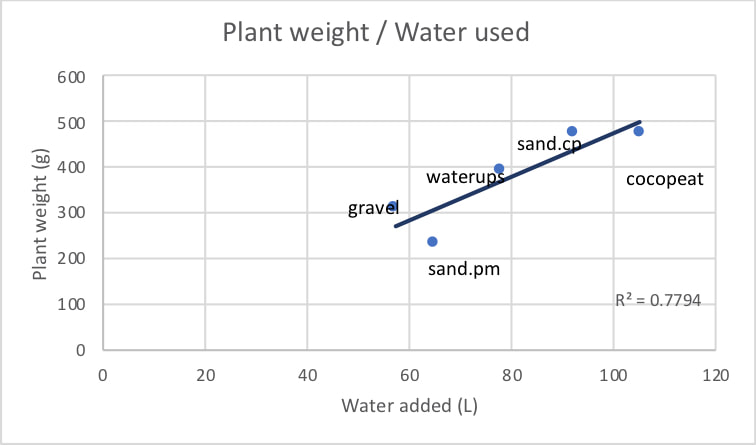

The Potting Mix was only used with a sand-filled reservoir. The Cocopeat Mix was used with all four reservoir materials. Three replicates of each combination were used. Spinach seedlings were planted on 17/10/19 and plants were harvested and weighed on 17/1/20. The water reservoirs were full at time of planting, topped up as needed through the experiment and refilled after harvest. The total amount of water added to each bed was recorded. The average plant weight per bed is shown in the following graph. The best growth was from the bed completely filled with Cocopeat Mix. The beds with a sand reservoir and Cocopeat Mix growing medium (labelled sand.cp) grew slightly less. The beds with the Potting Mix (sand.pm) grew the least. A wicking bed with a gravel reservoir and Cocopeat Mix growing medium was the worst performing of the beds for plant growth. The amount of water used was pretty much in line with the amount of growth, except for the Potting Mix wicking beds. The following graphs show the average amount of water used per bed and the correlation between the plant weight and the water used. Based on these results, the simple design using the Cocopeat Mix for both the reservoir and growing layers is best.

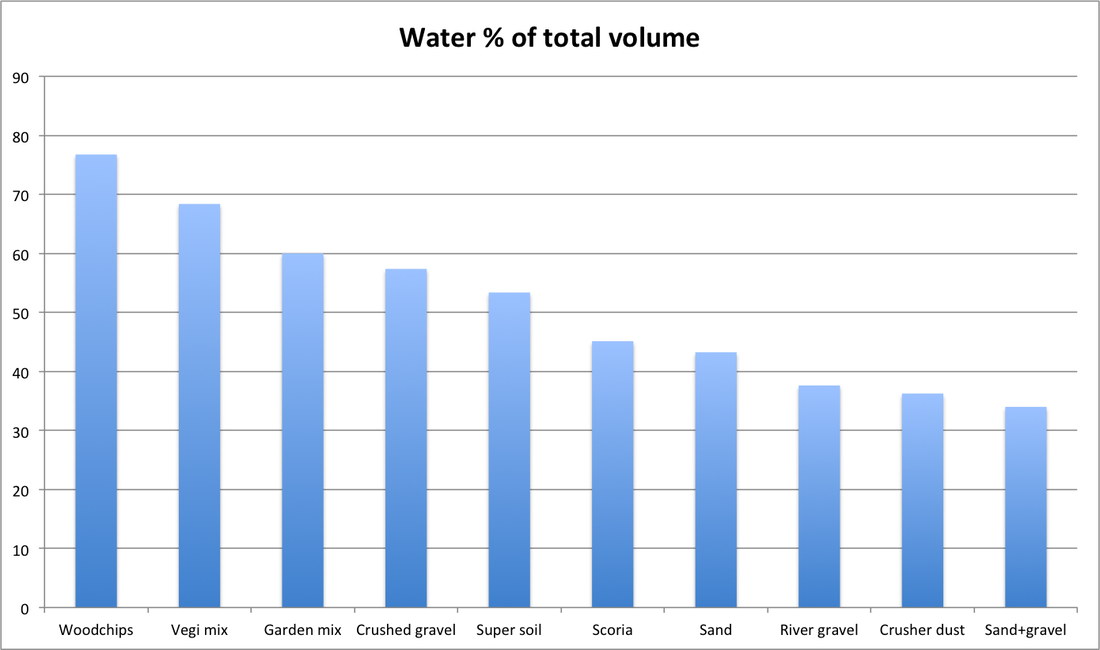

I have some concerns about the long-term performance of this design since I have found in other wicking beds that I have built that potting mix/compost in the reservoir decomposes anaerobically and deteriorates into a black sludge. I have had better long-term results using a 50:50 mix of garden soil and compost through the whole wicking bed but I haven't done a controlled experiment to test this yet. Washed sand in the reservoir layer appears to be a good choice and sand would not suffer from decomposition. I am not drawing any conclusions on the WaterUps product from this experiment. I filled the hollow legs of the WaterUps with coarse perlite and have subsequently found that this does not wick as well as perlite with smaller particles. In my next experiment I have replaced the perlite in the WaterUps with the cocopeat mix that I know does wick well. As I hypothesised before the start of this experiment, 10mm gravel did not perform well as a reservoir material. Gravel does not have good wicking properties and even though the reservoir was 200mm deep, only part of the water was able to wick up into the growing medium. I currently have the same wicking beds planted with lettuce and am recording more detailed measurements of soil moisture at various depths that should allow me to draw more certain conclusions about the better materials for wicking beds. I'll report on those results in the future. At the moment the lettuce growth is spectacular. Sixteen wicking beds are being constructed for the Honours wicking bed project. They are constructed in four IBC containers cut in half and then fitted with a divider across the middle of the half container. This allows two different materials to be trialled for the drainage layer in each half IBC. The dividers have to be waterproof. The green material is bathroom waterproofing paint left over from our bathroom. It was painted onto fabric and corflute panels and allowed to dry. It turned out that there was some leakage so pond liner was installed in the bottom of each wicking bed. A range of materials are being used inside the pond liner so their effectiveness can be measured and compared.  The material in the reservoir layer needs to do two things. The first is to wick water up into the growing media. The ability of various materials to do this was discussed in an earlier blog post. The second is to provide enough spaces between the particles to store a reasonable amount of water. The more water that is stored, the longer you can go before you have to add more water to the wicking bed. The graph shows how much water each material can hold, as a percentage of the volume of the material. I measured this by filling a container of a known volume with the material, then adding water until it came to the top of the container, level with the top of the material. I measured the amount of water added. The most water was held in woodchips and the coarser two soil mixes, but these materials would probably be more compacted when used in a wicking bed and thus probably hold less water. Of the traditional reservoir materials, the 10mm crushed gravel held the most water (57%), followed by scoria (45%) and sand (43%). For the water holding capacity criteria, 10mm crushed gravel would seem to be the best material to choose. But the capillary rise tests showed that gravel has very limited wicking capability compared to sand so, although sand will hold less water, I suspect it will prove a better material in the reservoir of a wicking bed. I will test this in a future experiment when I build wicking beds with various reservoir materials and measure the moisture movement through them. Two alternatives to using sand or gravel in the reservoir layer of a wicking bed are to use coarse organic material like straw or woodchips, or to just fill the whole wicking bed with soil and not have something different in the reservoir layer. I’ve done both and they both work.

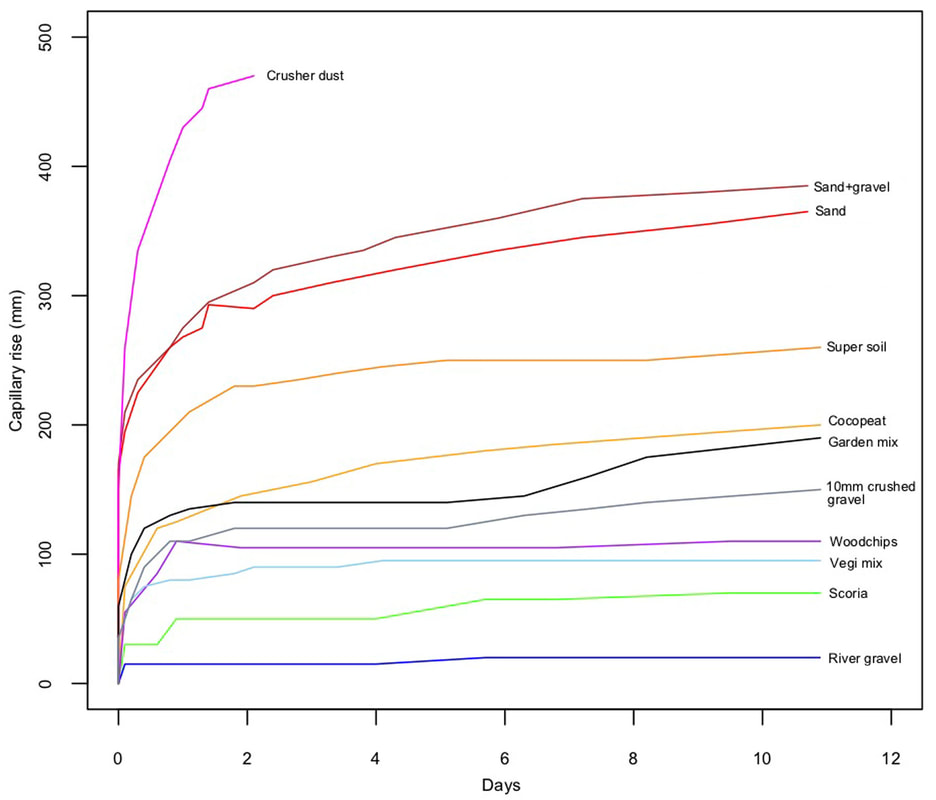

Not having different material in the reservoir is the simplest way of making a wicking bed. One criticism of this approach is that, since some of the soil will always be saturated, that it will decompose anaerobically and get smelly. I filled a couple of wicking beds with a mix of potting mix and mushroom compost. They did not smell but after a couple of years the material in the bottom had decomposed to a black sludge. More recently I have been using a 50:50 mix of garden soil and compost and this seems to survive being saturated and is ok after at least three years. I tested the wicking ability of small woodchips and three soil mixes in 50mm Perspex tubes. The soil mixes were from Corkhill Bros in Mitchell. All three are various combinations of topsoil, sand, manure and compost. Super soil has the most topsoil and vegi mix is much more like potting mix. Garden mix is somewhere between these two. The woodchips wicked water up 110mm so would be ok in a shallow reservoir layer. Of the soil mixes, super soil wicked up 260mm, garden mix 190mm, and vegi mix 95mm. The vegi mix has quite a few largish pieces of undecomposed woodchips and spaces around these in the narrow tube I was testing in may have hampered the wicking. All the soils would be more compacted in a wicking bed than they were in my tubes so this test may not be a fair indication of their wicking performance. I was interested to try pure cocopeat. This is often used in hydroponic systems but I have not heard of it in wicking beds. I think it could work if soluble fertiliser was used in the water as it is in hydroponics. However, the wicking ability of cocopeat was not great. At 200mm it was better than the garden mix, but not as much as you would need for a 500mm deep wicking bed. Again, it might worked better if it was more compressed. I’m beginning to wonder if a mix of sand and compost might be a good medium to use in wicking beds. Sand wicks well, and the compost would provide nutrients to the plants. More research needed…  The first experiment I am doing is to test the wicking capability of various materials. I am filling 50mm diameter Perspex tubes with the material and placing the bottom of the tube in a container of water. I am measuring the height that the water rises in the tube. The graph below shows the height and rate of wicking from my first round of tests. I will be repeating this a few times to see how consistent these results are. The materials I have used are:

The river gravel and scoria had almost no wicking ability so they would not be able to transfer water from the reservoir to the soil in a wicking bed. The crushed gravel was a bit better, wicking water up 150mm after almost two weeks. This gives the impression that this gravel may be ok as a reservoir layer (no more than 150mm deep) but the rate of wicking was slow and the amount of water wicked up was very small. The most impressive wicking was from the crusher dust. Water rose through this to the top of the tube (470mm) in only two days. Sand also performed well, wicking up 385mm (sand+gravel) and 365mm (sand). It would appear from this that sand would be better than gravel in the reservoir of a wicking bed. Crusher dust wicks even more but I have never heard of this being used in a wicking bed. I need to look into this further. In the next blog post I will look at wicking in soil, cocopeat and woodchips. I’ve been using wicking beds for many years and find them a terrific way to grow vegies. The constant moisture in them has produced the best lettuce and carrots I’ve ever grown and the rhubarb in the wicking bed has thrived through the last hot dry summer (unlike its relatives in the unwatered food forest). Having a water reservoir in the wicking bed means that I’m only watering them every two or three weeks, or even less often.

I started with the most common design – gravel for the water reservoir, then a layer of geotextile, then the soil. That worked OK but the geotextile got caught up when I dug new compost through the soil and the gravel was a real pain when I wanted to dig everything out to refresh the soil. For the last few years I have been using wicking beds with the whole container filled with a mix of soil and compost. The bottom of it is saturated where the water is held but that works fine and the plants grow well. It’s much simpler and cheaper than using gravel. But still, the vast majority of designs on the Internet use gravel. I’ve recently completed a Bachelor of Horticulture at Charles Sturt University. As part of this degree I did a couple of units in soil science. I learned about how water moves through soil and how capillary action – which causes wicking – needs small gaps between the soil particles to work. The large gaps between pieces of gravel won’t allow wicking to work very well. So I started to wonder how wicking beds with gravel actually work, and what is really the best material to use in them. There is very little in the scientific literature about wicking beds; only lots of opinions on the web and YouTube. So I’ve taken up the opportunity to do an Honours research project with the uni to test how well various wicking bed designs actually work. The project will continue through next year so I won’t have any definitive results for a while but I’ll post progress reports here from time to time to describe what I’m finding. If you’re really interested, you can read the details of what I’m going to do in my research proposal. |

Blog writer

Chris is exploring how wicking beds work for a Charles Sturt University honours project. This blog reports on the findings of this original research. Archives

July 2022

Categories |

||||||

RSS Feed

RSS Feed