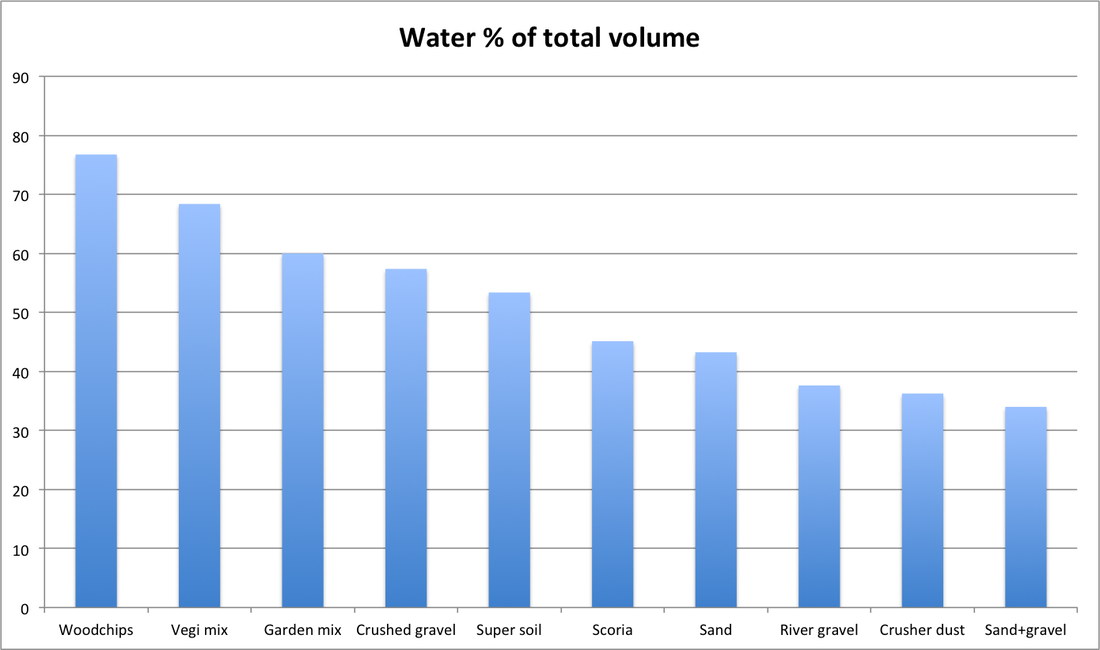

The material in the reservoir layer needs to do two things. The first is to wick water up into the growing media. The ability of various materials to do this was discussed in an earlier blog post. The second is to provide enough spaces between the particles to store a reasonable amount of water. The more water that is stored, the longer you can go before you have to add more water to the wicking bed. The graph shows how much water each material can hold, as a percentage of the volume of the material. I measured this by filling a container of a known volume with the material, then adding water until it came to the top of the container, level with the top of the material. I measured the amount of water added. The most water was held in woodchips and the coarser two soil mixes, but these materials would probably be more compacted when used in a wicking bed and thus probably hold less water. Of the traditional reservoir materials, the 10mm crushed gravel held the most water (57%), followed by scoria (45%) and sand (43%). For the water holding capacity criteria, 10mm crushed gravel would seem to be the best material to choose. But the capillary rise tests showed that gravel has very limited wicking capability compared to sand so, although sand will hold less water, I suspect it will prove a better material in the reservoir of a wicking bed. I will test this in a future experiment when I build wicking beds with various reservoir materials and measure the moisture movement through them.

3 Comments

Two alternatives to using sand or gravel in the reservoir layer of a wicking bed are to use coarse organic material like straw or woodchips, or to just fill the whole wicking bed with soil and not have something different in the reservoir layer. I’ve done both and they both work.

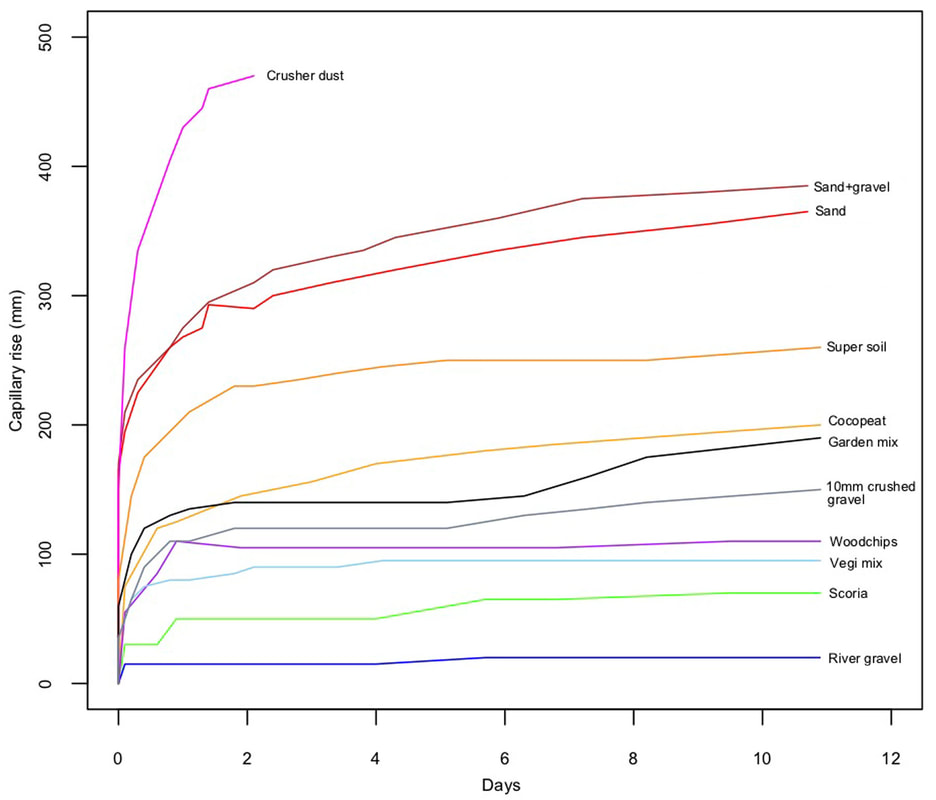

Not having different material in the reservoir is the simplest way of making a wicking bed. One criticism of this approach is that, since some of the soil will always be saturated, that it will decompose anaerobically and get smelly. I filled a couple of wicking beds with a mix of potting mix and mushroom compost. They did not smell but after a couple of years the material in the bottom had decomposed to a black sludge. More recently I have been using a 50:50 mix of garden soil and compost and this seems to survive being saturated and is ok after at least three years. I tested the wicking ability of small woodchips and three soil mixes in 50mm Perspex tubes. The soil mixes were from Corkhill Bros in Mitchell. All three are various combinations of topsoil, sand, manure and compost. Super soil has the most topsoil and vegi mix is much more like potting mix. Garden mix is somewhere between these two. The woodchips wicked water up 110mm so would be ok in a shallow reservoir layer. Of the soil mixes, super soil wicked up 260mm, garden mix 190mm, and vegi mix 95mm. The vegi mix has quite a few largish pieces of undecomposed woodchips and spaces around these in the narrow tube I was testing in may have hampered the wicking. All the soils would be more compacted in a wicking bed than they were in my tubes so this test may not be a fair indication of their wicking performance. I was interested to try pure cocopeat. This is often used in hydroponic systems but I have not heard of it in wicking beds. I think it could work if soluble fertiliser was used in the water as it is in hydroponics. However, the wicking ability of cocopeat was not great. At 200mm it was better than the garden mix, but not as much as you would need for a 500mm deep wicking bed. Again, it might worked better if it was more compressed. I’m beginning to wonder if a mix of sand and compost might be a good medium to use in wicking beds. Sand wicks well, and the compost would provide nutrients to the plants. More research needed…  The first experiment I am doing is to test the wicking capability of various materials. I am filling 50mm diameter Perspex tubes with the material and placing the bottom of the tube in a container of water. I am measuring the height that the water rises in the tube. The graph below shows the height and rate of wicking from my first round of tests. I will be repeating this a few times to see how consistent these results are. The materials I have used are:

The river gravel and scoria had almost no wicking ability so they would not be able to transfer water from the reservoir to the soil in a wicking bed. The crushed gravel was a bit better, wicking water up 150mm after almost two weeks. This gives the impression that this gravel may be ok as a reservoir layer (no more than 150mm deep) but the rate of wicking was slow and the amount of water wicked up was very small. The most impressive wicking was from the crusher dust. Water rose through this to the top of the tube (470mm) in only two days. Sand also performed well, wicking up 385mm (sand+gravel) and 365mm (sand). It would appear from this that sand would be better than gravel in the reservoir of a wicking bed. Crusher dust wicks even more but I have never heard of this being used in a wicking bed. I need to look into this further. In the next blog post I will look at wicking in soil, cocopeat and woodchips. |

Blog writer

Chris is exploring how wicking beds work for a Charles Sturt University honours project. This blog reports on the findings of this original research. Archives

July 2022

Categories |

RSS Feed

RSS Feed